Packaging Details: Standard sea packing or as customer's request

Delivery Time: 3-15 working days according to the number of orders placed by customers

Payment Terms:L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: Supply 100,000 pieces per month

Model Number:OEM customization

If you have any questions, please feel free to contact us.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— PRODUCT INTRODUCTION

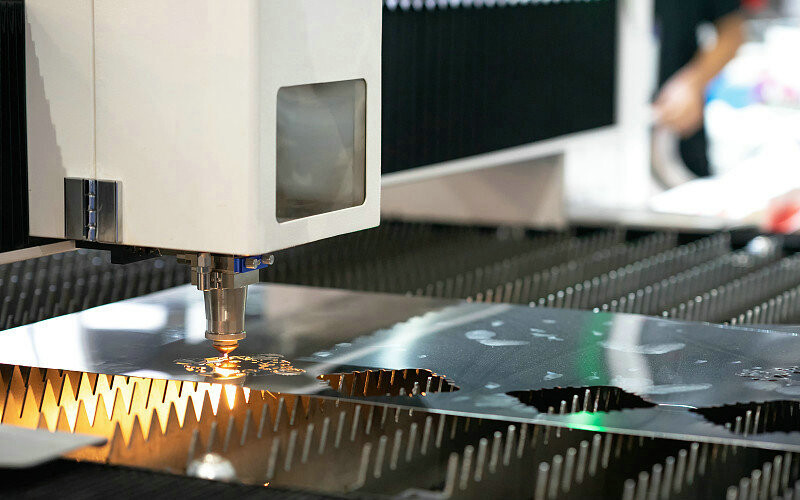

Free Sample Laser Cutting Stainless Steel Sheet Metal Fabrication Service/OEM Laser Marking Logo Service

What is sheet metal bending?

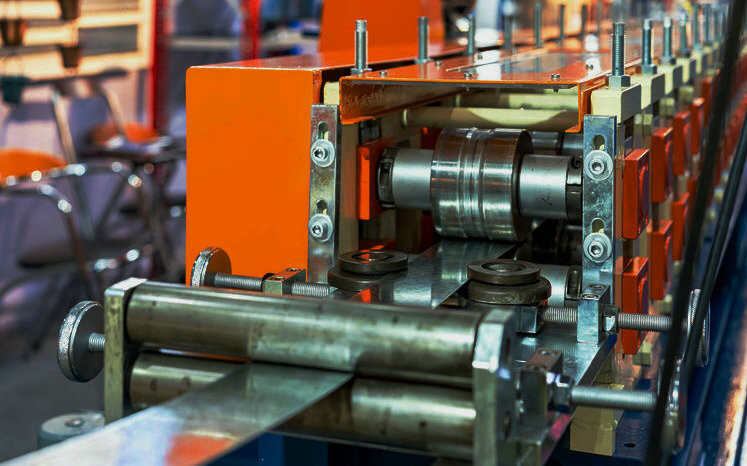

CNC bending (combined with laser cutting) is one of the most underrated processes in small to medium batch sheet metal production, especially when the quantities (hundreds to thousands or more per batch) are not high enough to justify the high cost and difficulty of manufacturing Situations where maintenance of stamping tools, or where production speed and flexibility are important. The ability to produce parts in a variety of geometries without tools, fast lead times, high levels of repeatability and automation mean sheet metal bending is a key tool for product developers, engineers and business owners looking to manufacture metal parts

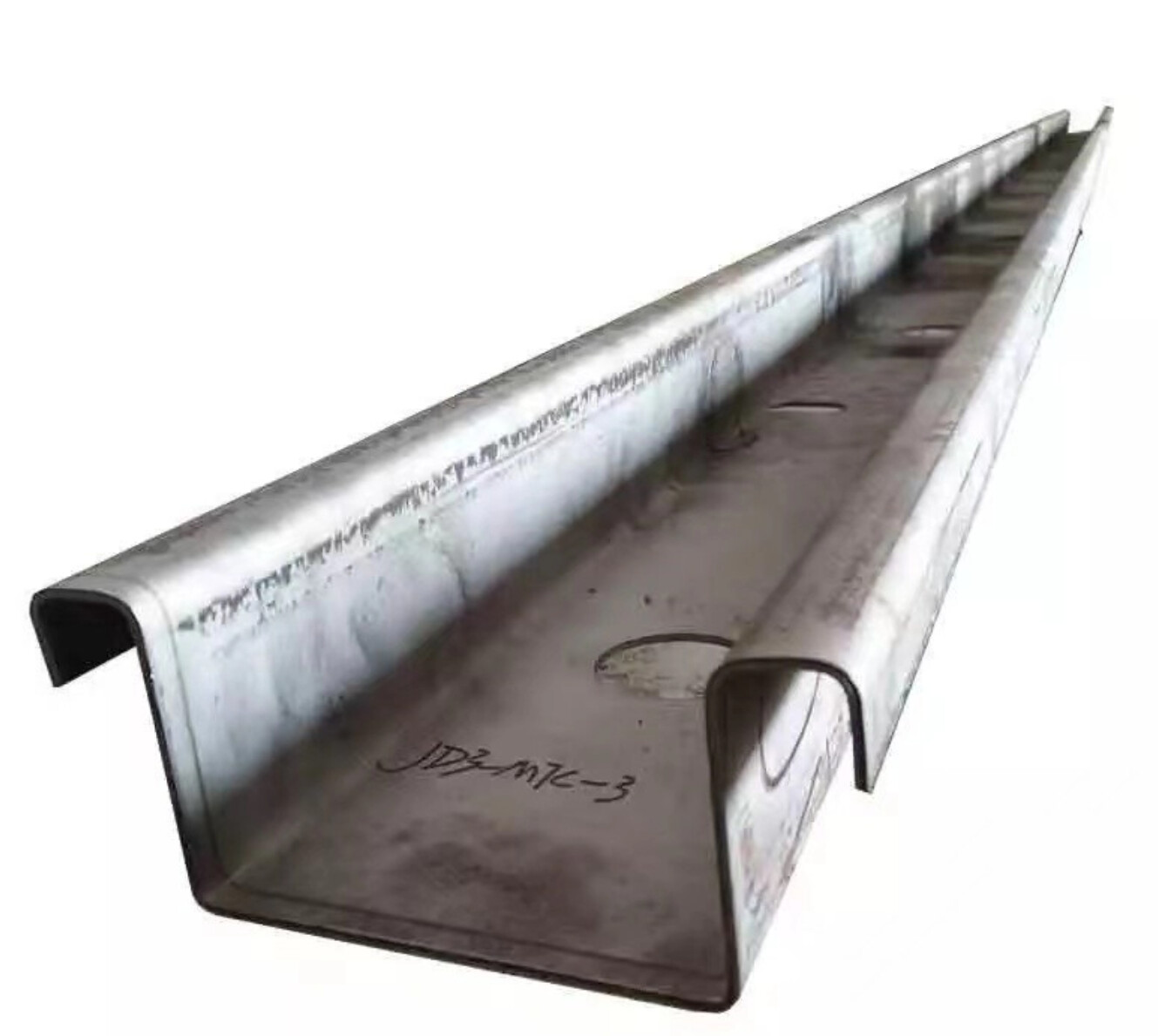

Even at the design stage, understanding the bending possibilities of sheet metal is important because it is a tool that gives engineers great flexibility to create a variety of shapes and, in many cases, allows parts to be created from a single piece of material , rather than joining multiple parts together by hardware or welding, reducing overall cost and increasing strength, simplifying assembly and requiring few tools

OEM CNC Metal Bending

TUV CNC Metal Bending part

laser cutting stainless steel sheet

advantage

Manufacturing Speed - Once designed and programmed, sheet metal parts can be produced very quickly, enabling a large number of components to be produced in produced in a relatively short period of time

Accuracy - Sheet metal parts can be very precise, with laser cut holes within ±0.1mm, if adequate design considerations are given. There is a high level of repeatability here, as programmed laser cutters and CNC press brakes with appropriate software and equipment are produced with low variability

Less post-processing – Welding often requires multiple passes to complete a part; heat typically deforms the material and requires straightening, and time-consuming and labor-intensive grinding and polishing are required to remove weld spatter. Bending doesn't have these problems - the part is ready to go straight from production

Lighter weight - Due to the complexity of the available bending, stiffness and strength can be achieved while using relatively less material, thereby also reducing part weight. It benefits every step of the supply chain, including shipping

Low cost and virtually no tools - Thanks to advances in technology, CNC cutting and bending reduces the manual labor required to produce parts, sheet metal bending processes benefit from this technology more than most, using CNC-controlled tools, parts can be made by skilled workers Lower workers produce in less time, all resulting in lower final costs

Laser cutting and sheet metal bending processes generally do not require specialized tools, as most manufacturers carry a range of general-purpose tools that can produce most standard bends. This means no tooling investment and significantly reduced lead times, as there is no need to wait for complex tooling to be produced, tested or adjusted

High-precision process is ideal when high precision is required

Can be mass-produced in a short time

Low production cost and low mold cost

laser cutting stainless steel sheet

Suitable for high or small batch production

Multiple custom shapes can be created through a range of bending processes

Standard punches and dies available, including V and U shapes

Product Description

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— ABOUT US

Jiangsu Hailiang Dongfang Import and Export Co., Ltd. is a professional metal parts manufacturer with years of experience in the industry, specializing in the production of various precision metal parts. Our business covers a wide range of areas, including CNC machining, metal stamping, mold parts manufacturing, forging, and casting, to meet the diverse needs of our customers. As a quality focused enterprise, we are committed to providing high-quality products at highly competitive prices. Every process is strictly controlled, and all products are screened layer by layer by advanced testing equipment and professional inspection teams to ensure their excellent performance, safety, and reliability. In addition, we attach great importance to after-sales service and have a professional and efficient customer service team to provide technical support and solutions to customers at any time, ensuring that customers have no worries during use. Jiangsu Hailiang Dongfang Import and Export Co., Ltd. has won the trust and praise of its customers with exquisite craftsmanship, strict quality management, and attentive service.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— WHY CHOOSE US

High quality raw materials

Selecting high-quality steel raw materials ensures excellent product quality and performance from the source, leaving your project worry free.

Strict quality control

With advanced testing equipment and a professional team, all products undergo multi-stage rigorous testing to meet international standards, ensuring reliable and guaranteed quality.

Efficient logistics service

Cooperate with well-known logistics companies to establish a global logistics network, ensure fast and accurate delivery of goods, and ensure that your project progress is not affected.

after-sales team

An experienced after-sales team is always on standby to solve any problems you may encounter during use, providing technical support and attentive service.

Competitive Price

Factory direct sales, providing customers with more cost-effective products.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— LEAVE A MESSAGE

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

—— RECOMMENDED PRODUCTS

ASK FOR A QUOTE